Alan doolittle pxtepe evaporation h nkt o ea kt 31012 3 2 1 2 j p ktm 2 2 r m k p t area d r evaporation 24 22 for evaporation the vapor pressure is where is the surface tension of the liquid n is avagadro s number and h is the enthalpy of evaporation.

E beam evaporation thin film deposition pdf.

As the deposition rate is increased from 3 5 å s the grain size decreases and sublimes film coverage improves.

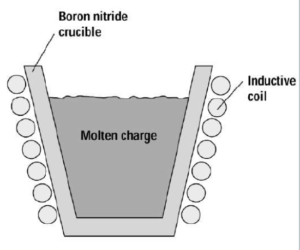

Thin film evaporation systems can also be configured with various hardware or software options.

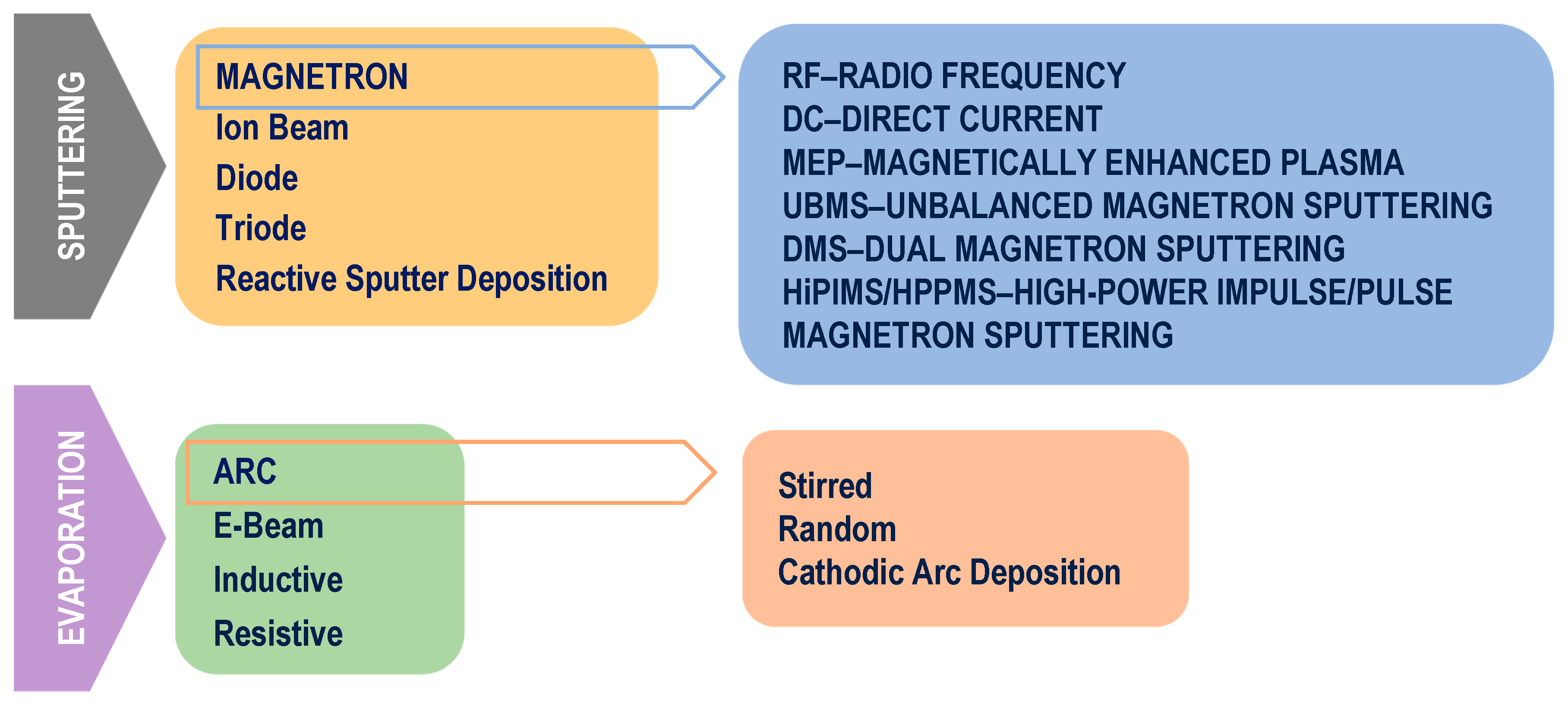

Physical sputtering uses ionized gases ar to move material from the target to the substrate.

Sih 4 g o 2æsio 2 s 2h 2 g silicon nitride.

3sih 4 4nh 3 æsi 3n 4 12 h 2 tungsten.

Sb 630 6 68 279 345 425 ebeam fair bn graphite al.

Sequential deposition advantage of e beam evaporation.

Alternatively some modern ebpvd systems utilize an arc suppression system and can be operated at vacuum levels as low.

E beam evaporation allows the evaporation of a wider range of metals with higher melting points.

Dielectric films sio2 si3n4 al2o3 can be produced from dielectric targets and rf power or else reactively sputtered in.

Ebeam evaporation of al si alloys is possible but sputter deposition is a better approach.

Evaporation is a well known technique used in the manufacture of tfscs.

Thin films are formed by depositing material on a clean suitable substrate to.

Chen 4 12 2004 cims sharon e beam evaporator.

Most thermal filament or e beam evaporation pvd systems include quartz crystal deposition control whereby real time deposition rate monitoring and control takes most of the work out of achieving the right thickness.

A thin film is a layer of material whose thickness varied from micrometer to nanometer 73.

Very low container contamination.

Applied physics 298r 13 e.

Laser beam evaporation pulsed laser deposition pulsed laser deposition pld is another physical deposition technique to deposit the thin film coating system.

619 6 5 600 ebeam.

Applied physics 298r 14 e.

Reported the deposition of czts precursors film by electron beam evaporation in 1997 constituted of a sequential stack of zn sn and cu layers respectively on a mo coated slg substrate heated to 150 c under high vacuum.

Chen 4 12 2004 comparison 3000 ºc high.

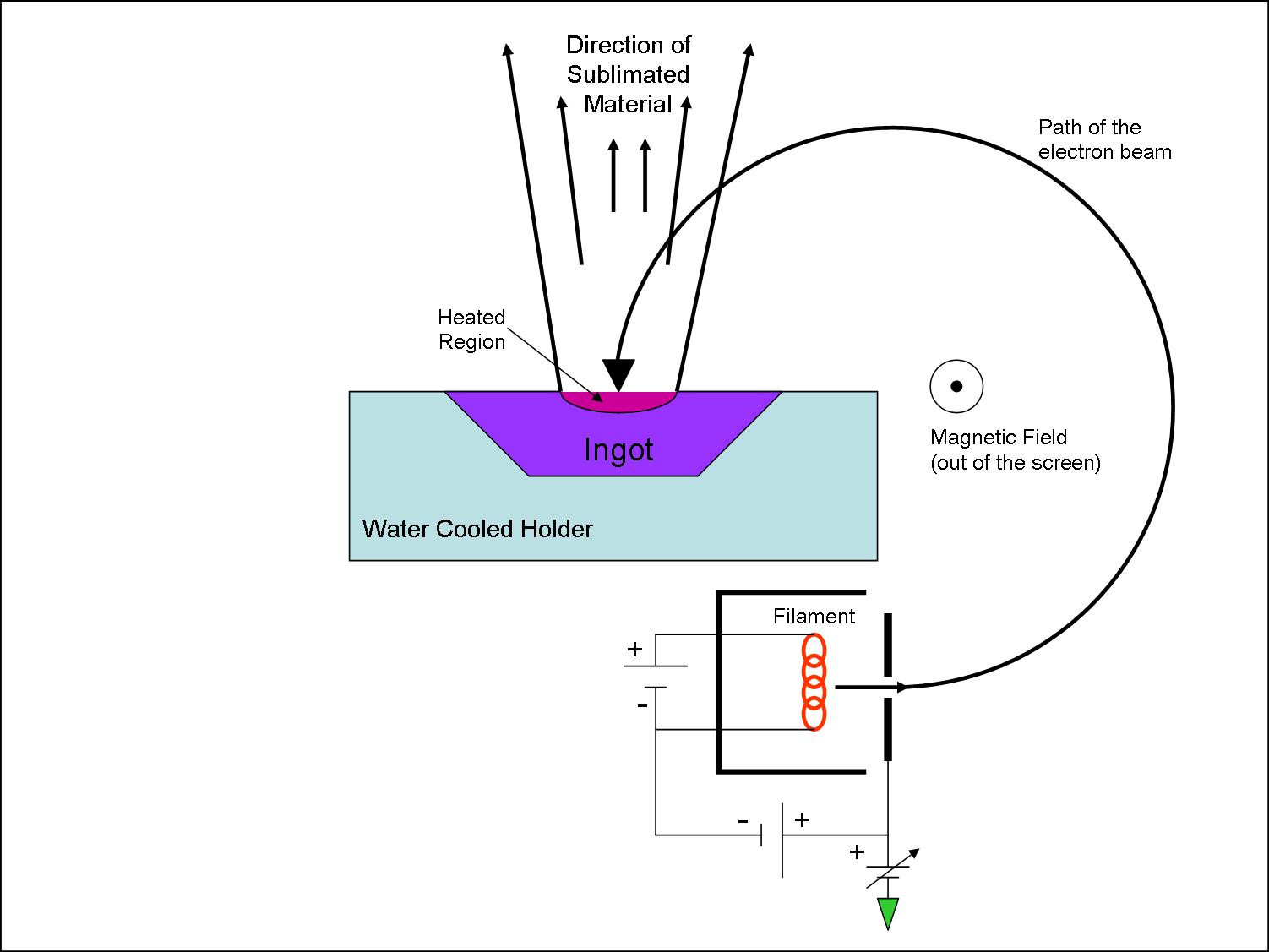

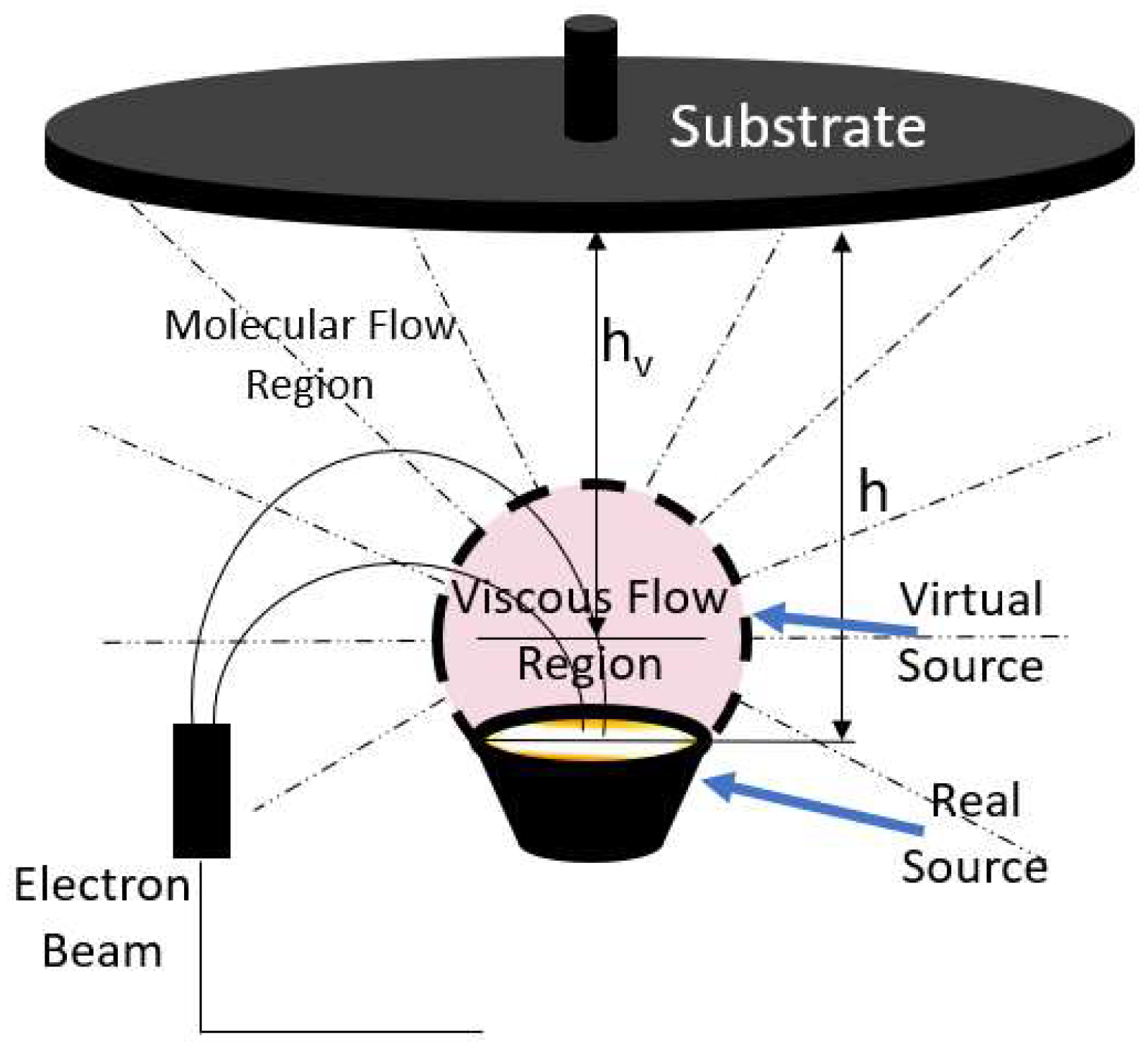

In an ebpvd system the deposition chamber must be evacuated to a pressure of at least 7 5 10 5 torr 10 2 pa to allow passage of electrons from the electron gun to the evaporation material which can be in the form of an ingot or rod.

During the thin film deposition process the laser beam is used to ablate the material for depositing the thin films inside a vacuum chamber as shown in figure 3.

Thin film deposition methods 2 1 introduction any object with one of its physical dimensions length breadth and height less than that of the other two is called a thin film.

Sih 4 g æsi s 2h 2 g silicon dioxide.